Features

² Principle of infrared particledetecting

² 100% calibration infactory

² Unique algorithm and compensation to gethighaccuracy

² Minimum detection particle size is0.5μm

² Suitable for air purifier and fresh airsystem

Product Series

|

Series Model |

Standard |

Common |

Slim |

Infrared Upgrade |

Mini Type |

Outdoor |

Infrared Type |

|

PM-D4 |

★ |

|

|

|

|

|

|

|

PM-G3 |

|

★ |

|

|

|

|

|

|

PM-E5 |

★ |

☆ |

|

|

|

|

|

|

PM-G7 |

|

★ |

★ |

|

|

|

|

|

PM-G7M |

|

★ |

★ |

|

|

|

|

|

PM-T7 |

★ |

☆ |

★ |

|

|

|

|

|

PM-T7M |

★ |

☆ |

★ |

|

|

|

|

|

PM-R3 |

|

|

|

★ |

|

|

|

|

PM-H3 |

|

★ |

|

|

|

|

|

|

PM-S1 |

☆ |

★ |

|

|

★ |

|

|

|

PM-SP1 |

|

|

|

|

|

★ |

|

|

PM-A3 |

|

|

|

|

|

|

★ |

|

PM-C3 |

|

|

|

|

|

|

★ |

★:Availableinallcases ☆:Availablein some cases Standard Series:Patentedproduct

Common Series:Compatible with other models in the market Slim Series:Slim design, only 12mm thick

Mini Type Series:Designed for space saving, mini size

Infrared Upgrade:Laser principle, used to upgrade mainstream infrared sensors on the market Outdoor Series:Specially designed for the harsh outdoor environment

Infrared Type Series:Infrared scattering principle, low cost

Specification

|

Item |

Type |

|

Minimum particle size |

>0.5μm |

|

Range |

0~1000μg/m3 |

|

Maximumconsistencyerror (PM2.5 concentration)(25±5)℃,(50 ±10)%RH, |

±20%, @(100~1000)μg/m3 ±20μg/ m3,@(0~100)μg/ m3 |

|

Output |

UART@4.5V |

|

PWM@4.5V |

|

|

I/o electric |

(VIH):1.8V~4.5V |

|

(VIL)<0.8V |

|

|

(VOH):3.3V~4.5V |

|

|

(VOL)<0.4V |

|

|

Power supply |

5V(4.8V~5.5V) |

|

Working Current |

<30mA |

|

working temperature/humidity |

(0~50)℃ / (0~99)% RH(notcondensate) |

|

Storage temperature |

–20℃ ~60℃ |

|

Stabilization time |

About 30sec |

|

Size |

46.2*34.1*18mm |

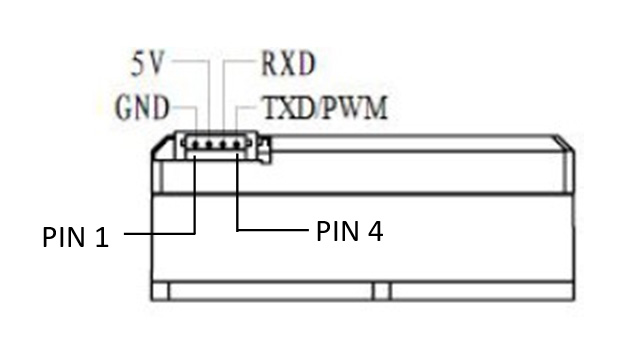

I/O Interface Definition

Pin Description

|

PIN No. |

PIN Function |

PIN Description |

|

PIN1 |

GND |

Ground |

|

PIN2 |

VCC |

Power Supply |

|

PIN3 |

RXD |

UART Digital Input |

|

PIN4 |

TXD/PWM |

UART Digital Output /PWM Output |

|

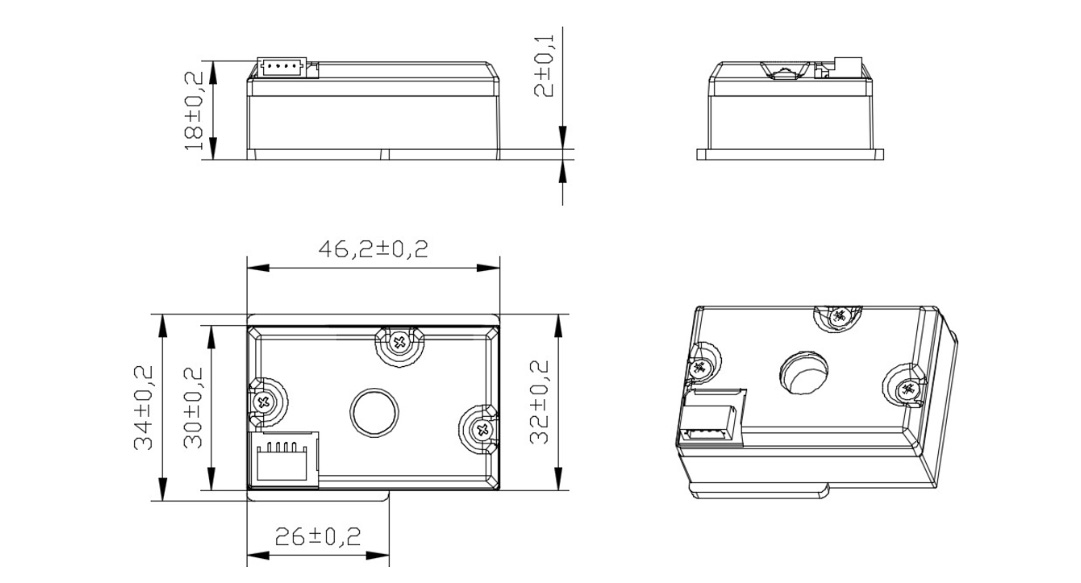

Dimensions(Unit : mm)

|

|

|

|

|

|

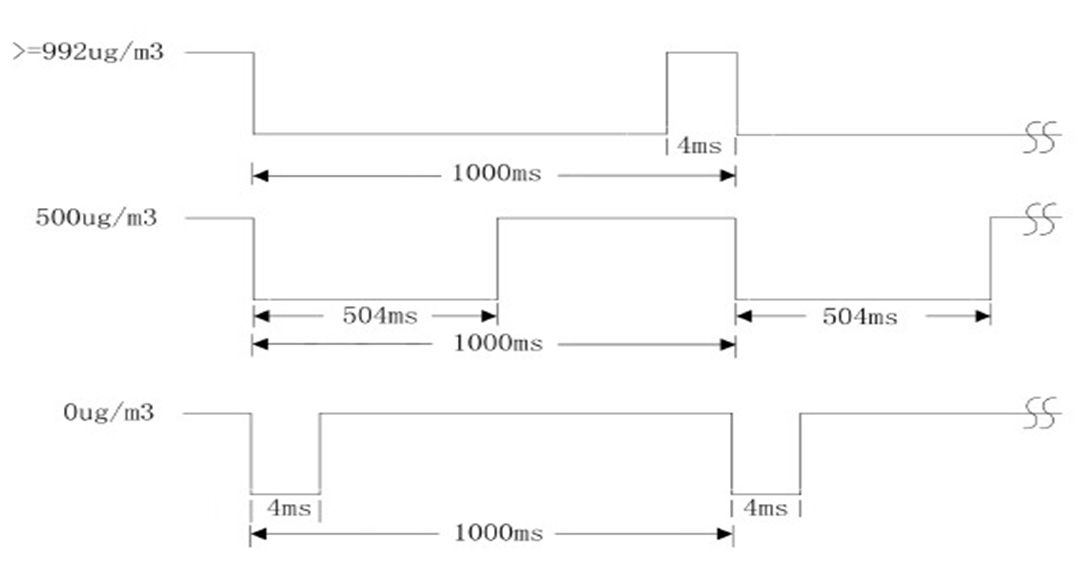

Ø TTLOutput(4.5V)

Ø Baud Rate:9600 bps ,Check Bit:none ,Stop Bit:1,32 bytes DataPackage

Circuit Design

|

|

|

|

|

|

Note of the circuit design:

1. The sensor is 5V powersupply.The sensor has no reverse protection.Itcannot be reversed connected.Itis recommended to add a 100μF capacitor to the power supply forfiltering.

2. Other I/O pins are 4.5V levelinterfaces.

3. PIN 3 is the RXD port. If it is not used, it is recommended to be notconnected.

Note

1. Mounting and fixed:The sensor recommended use the card buckie tofixed;

2. Inlet and outlet can not be intercepted between the measurement environment;

3. The air inlet and outlet must be in a plane close to the outside wall of the equipment and communicate with the outside by using the air holes, while keeping away from the position of largerairflow.

4. The inlet and outlet of the equipment should be greater than or equal to the size of the sensor inlet and outlet, and ensure that all the inlet and outlet areexposed.

5. Equipment designed air duct do not have corners, to ensure the airflow can be measured and go into the sensor;

6. When the sensor is in use, ensure that it works in a dark environment, reducing the interference of ambientlight.

7. When applied to purifiers or fixed testing equipment, the working position of the sensor should be higher than 20cm above the ground to prevent the large particles of dust and floccules in that causing the measurementerror;

8. Sensor be should away from the higher fever and radiationcomponents;

9. When the sensor is used in outdoor equipment, the protection of large particulate dust, rain andsnow,willow catkins and so on should be completed by the structure of theequipment

.Others

1. Due to the electrostatic sensitive components on the module, installation and use of anti-static facility is necessary, such as wearing anti-staticgloves;

2. In the process of installation, avoid non-standard operation such as hotswap;

3. Do not disassemble the sensor, or it will lead to irreversibledamage;

4. The sensor is designed for indoor air quality measurement. If the equipment is working in the following actual environment, the necessary design should be added to make sure the sensor shows good consistency and long servicelife,

a) the annual dust concentration greater than 300 micrograms per cubic meter for more than 50% of the time, or more than 500 micrograms per cubic meter for more than 20% of the time;

b) a fume environment, such as akitchen;

c) high water fog environment, such as bathroom.